business process improvement (BPI)

What is business process improvement?

Business process improvement (BPI) is a practice in which enterprise leaders analyze their business processes to identify areas where they can improve accuracy, effectiveness and efficiency and then make changes within the processes to realize these improvements.

BPI works by identifying the operations, employee skills or enabling technologies that could be improved or added to encourage smoother procedures, more efficient workflow and overall business growth.

This process, also known as functional process improvement, is part of the broader management discipline of business process management.

What is the purpose of business process improvement?

The primary objective of BPI is to continuously improve the performance of both the formal and informal processes within an organization. By engaging in business process improvement, organizations can identify bottlenecks, friction, inefficiencies and other problems within their processes and take corrective actions, which helps them to do the following:

- cut costs;

- eliminate redundant efforts;

- ensure continued adherence to workflows and better compliance with rules and regulations;

- improve quality of their products or services;

- reduce errors; and

- speed output.

Additionally, BPI techniques can help an enterprise meet customer demands and business goals more effectively. Business process improvement also creates value in its ability to help enterprises fine-tune how they operate to ensure they are positioned to compete in today's technology-driven business environment.

How does business process improvement work?

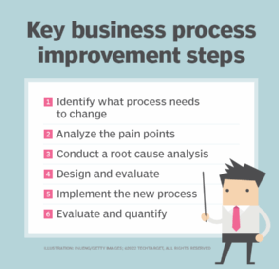

Business process improvement generally involves the following steps:

- Identify what process needs to change. This is typically done through business process mapping or other visualization of the steps, activities and workflows within the process.

- Analyze the pain points. This step includes identifying bottlenecks, inefficiencies, redundancies and other pain points within the workflow by using visualization tools as well as input from stakeholders.

- Conduct a root cause analysis. This helps to determine a strategy for how best to improve or eliminate problem areas.

- Design and evaluate. This could entail streamlining activities, reskilling workers or adding new technology such as robotic process automation (RPA); this step should also include analyzing and testing the proposed solution to ensure it does not have unintended negative consequences.

- Implement the new process. Change management techniques can help ensure successful adoption of the new or revised activity or technology.

- Evaluate and quantify. Reviewing metrics helps to ensure process changes have taken place and to assess the outcome.

Business process improvement methodologies

Managers engaged in business process improvement typically use one or more of the following methodologies to work through the task:

- Agile management. Coming from the world of software development, this approach brings cross-functional teams together to work in short production cycles called sprints to either improve or add technology features and functions as a way to enhance a business process.

- Lean management. Rooted in manufacturing, and most notably with the carmaker Toyota, the focus of lean management is to reduce waste and use the fewest resources to achieve the end product; it also promotes continuous improvement and ways to increase efficiencies within a process. Lean encompasses the following:

- Kaizen, an approach that calls for small, ongoing changes that build up to significant improvements;

- 5S, a related checklist-based approach built on Japanese words typically translated as sort, set in order, shine, standardize and sustain;

- plan-do-check-act, a model for testing, analyzing and improving; and

- the Total Quality Management (TQM) framework.

- Six Sigma. Also developed in the manufacturing industry, the Six Sigma methodology uses data and empirical and statistical tools to analyze deficiencies and drive improvements. Six Sigma adherents often use DMAIC -- define, measure, analyze, improve and control -- to study and optimize existing processes.

- Theory of Constraints. This methodology enables managers to identify the most significant constraint currently blocking improvements or organizational objectives and then focus on improving processes until that constraint is no longer an obstacle.

In addition to these and other process improvement techniques, enterprise executives and managers typically use various tools to understand and gain visibility into their business process. Those tools include the following:

- business process mapping;

- kanban to manage and track work as it flows through a process; and

- value stream mapping to record the repeatable steps in the process.

Business process improvement examples and use cases

Business process improvement typically delivers value by eliminating or improving bottlenecks, inefficiencies and redundancies within the entire process through workflow changes or the redeployment of resources – either people or technology. Broad examples of this include the following:

- moving from paper to digital documentation to speed processing;

- using automation to eliminate tedious, slow and error-prone manual work; and

- the introduction of data analytics, machine learning, natural language processing or other intelligent technologies to boost speed, improve productivity and eliminate the use of superfluous resources.

Benefits and challenges of business process improvement

Each of the benefits of BPI is significant, but an enterprise with a strong BPI discipline can also improve the following with optimized processes:

- customer service, customer experience and ultimately customer satisfaction;

- worker experience; and

- automation, innovation and intelligence to processes, all of which support continuous enterprise transformation.

Together, these can help boost an organization's ability to compete in the market.

There are, however, the following challenges to implementing a successful BPI program:

- workers' resistance to change;

- unplanned improvements are not aligned to business goals; and

- lack of communication across the organization to relevant parties.

Business process improvement best practices

Best practices to follow for a strong BPI discipline within an organization include the following:

- Ensure the organization has well-documented processes with good visibility into the workflows that make up those processes and all the positions, systems and data that support them.

- Adopt a methodology for analyzing processes and identifying opportunities to improve them.

- Commit adequate resources to support BPI as an ongoing exercise within the organization.

- Solicit input and ideas from process stakeholders on possible areas of improvement.

- Similarly, communicate improvement strategies to stakeholders to ensure buy-in.

- Invest in adequate change management programs, including employee training, to ensure the successful implementation of improvement strategies.

- Monitor results to ensure compliance with changed workflows within recently improved processes.

- Establish metrics to measure the success of improvements.

- Use those improvement metrics to gain executive support for additional BPI projects.

- Incorporate the BPI discipline into an overall BPM practice.

Although workflow and BPM work together, they have very different functions. Learn what sets these two business processes apart.